SERVICES AND EQUIPMENT

PRECISION GRINDING

PS Engineering specializes in precision grinding of components . We consistently deliver superior quality due to our hands on management approach and internal ISO quality tracking system. We have a range of external and internal grinding lathes, surface grinders and cylindrical grinders to handle a multitude of grinding applications.

Our grinders are able to do diamond grinding which is important as our coatings are extremely hard (1400 HV hardness can be achieved). We can grind Tungsten carbides, Chrome Carbides, Ceramics, Stellite and Hard Chrome coatings.

PS Engineering has an in-

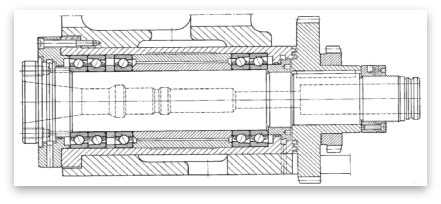

We can manufacture and repair precision components.

Shafts and rollers can be re-

Refurbishing or manufacturing components.

Furthermore we quote on CNC, Heat treatment, deep drilling, keyways and slots.

MACHINING

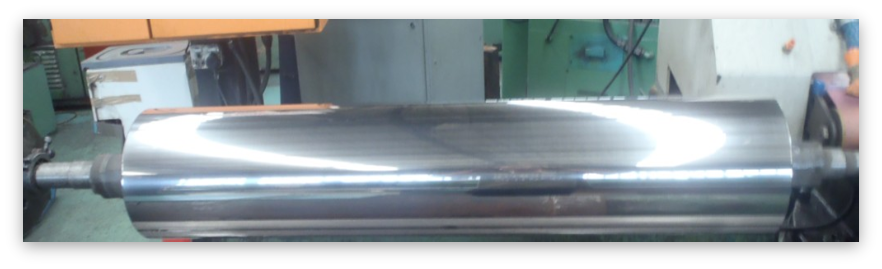

SUPERFINISHING

PS Engineering is proud to offer Superfinishing services. Superfinishing and Superpolishing makes it possible to create super smooth surfaces measured in Ra micron finishes. We can achieve mirror finishes even on super hard materials such as Tungsten carbide coatings, ceramics and chrome carbides.

Superfinishes are usually critical in applications where a low coefficient of friction is required or quick release applications. The printing and packaging industry usually requires such high tech coatings and performance. We can easily and consistently achieve the finest tolerances in finishes due to our quality finishing systems.

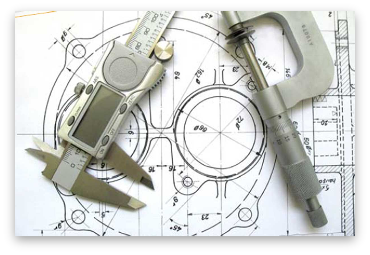

QUALITY CONTROL

PS Engineering adheres to strict standards of quality control. Every component is thoroughly documented on a digital internal ISO system. A thorough Pre-

Our measuring equipment is calibrated and kept in a temperature controlled environment to ensure accuracy. We have a granite surface inspection table which provides a perfectly square and flat surface to measure components on. We have micrometers, Depth gauges, surface roughness testers, film thickness testers and hardness testers.

“We continuously train our personnel and review our processes

to improve our service to our customers.”

Our Thermal Spray facility is a technologically advanced system to coat new or worn surfaces. Worn engineering components can be salvaged for a fraction of the cost of purchasing a new one.

Our Supersonic Ultra Hard Carbide HVOF system can coat substrates and surfaces at speeds exceeding Mach1. This allows for very dense and wear resistant coatings of Tungsten carbide,Chrome Carbide, Nickel and Stellite. This application is surpassing and replacing several traditional Hard Chroming and Flash Chroming applications in industries worldwide.

THERMAL SPRAY SURFACE COATING

Our Thermal Arc Spray System offers the ability to recoat badly worn components to original spec. An improved component can be engineered by simply coating the old substrate with an improved or superior alloy.

The twin wire arc system can spray a mixture of alloys which can make it possible to create pseudo-

Copyright © 2015 -

COATING -